1. September 2021

Breathe IN / Breathe OUT

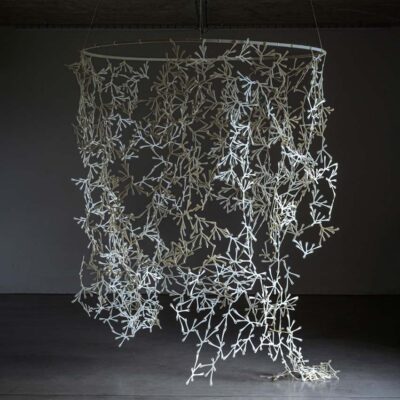

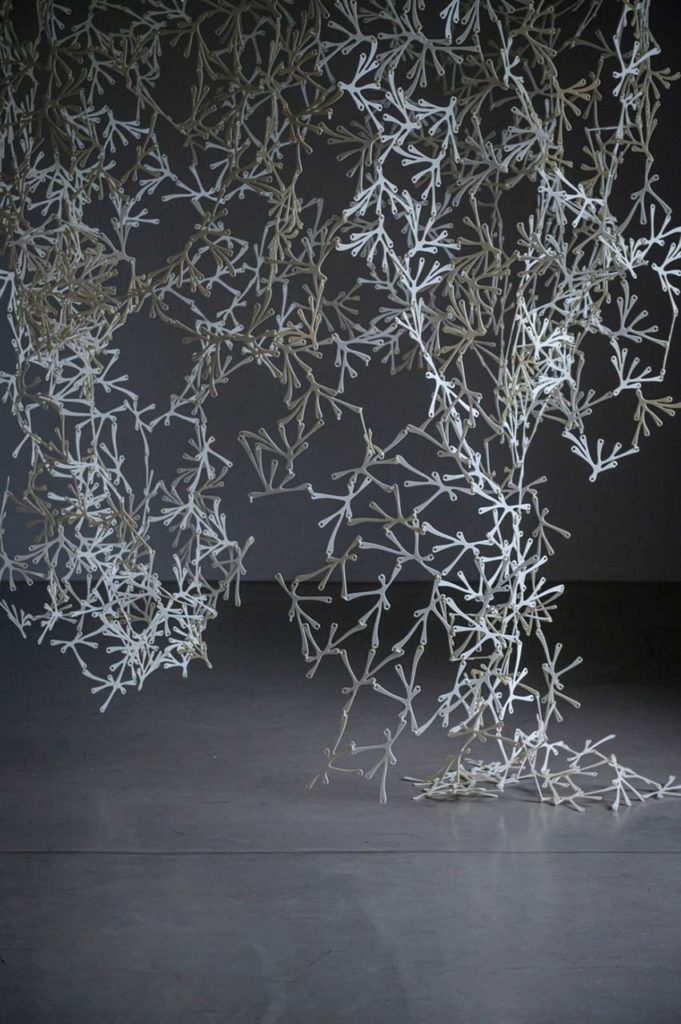

The between Berlin and Bratislava based studio crafting plastics! is represented in the VIENNA BIENNALE FOR CHANGE 2021 (28 May – 3 October 2021) with their installation Breathe IN / Breathe OUT (2021). The crafting plastic! studio was founded in 2016 by product designer Vlasta Kubušová and production designer Miroslav Král. Marlies Wirth, Curator, Digital Culture and MAK Design Collection interviewed the designers about their current project for the blog post.

Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK)

Breathe IN / Breathe OUT, 2021

3D printed 100 % biobased and biodegradable polymer blend

© Adam Šakový

MAK: For your project Breathe IN / Breathe OUT that is now on view at MAK on occasion of VIENNA BIENNALE in the exhibition CLIMATE CARE: Reimagining Shared Planetary Futures you developed a unique modular installation of 3D printed polymer blend. You have conceived a completely biobased and biodegradable material that has the material attributes of plastics, but is not plastic.

How did you develop the idea and can you tell us more about the process?

The crafting plastic! studio: In 2018 we started to work together with Moritz Maria Karl on the idea of creating an experimental building material for interior architecture with the use of our developed bioplastics. By discussing the complexity of challenges when integrating bioplastics for longer-lasting products, we found out that these new materials are missing their own identity. Technically they belong to the group of plastics, because of their thermoplastic properties and processing technology, but they are made from natural resources and are perishable when they are disposed of properly. Materials that we are working with (100% natural biopolymer blends) can serve as an alternative for the synthetic plastic materials, but not only. It is not the exact 1:1 material replacement that we need when we want to get rid of the oil based materials. We need to create new acceptance for the natural alternatives and enhance their own features and properties, respecting where they came from and their entire lifecycle. In crafting plastics! studio we optimise various natural biopolymers to create specific blends according to the product’s needs. In Breathe In/ Breathe Out, together with Moritz we explore the relationship between these new materials, space and their new unexpected feature – smell.

- Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK) Breathe IN / Breathe OUT, 2021 3D printed 100 % biobased and biodegradable polymer blend © Adam Šakový

- Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK) Breathe IN / Breathe OUT, 2021 3D printed 100 % biobased and biodegradable polymer blend © Adam Šakový

MAK: The title Breathe IN / Breathe OUT already hints towards another layer of this unique project: you have developed specific scents for the biobased polymer blends that actively work with our brain. Materials currently used in architecture, interior and product design are primarily perceived by way of visual and tactile properties. Olfactory properties are much less prominent. However, scent as such plays a central role in the emotional acceptance of a material and decisively determines its distinctive character.

Please tell us more about your approach towards developing the scents for the installation and why the olfactory component is so important.

The crafting plastic! studio: One of the challenges in implementing bioplastics on a larger scale is that it is very difficult for the user to identify whether the product is made from petrol-based plastics or a biocomposite. The sense of smell can add an additional material property and help to distinguish natural and synthetic materials. Also, we think that many future materials are judged by performance and visual appearance.

Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK)

Breathe IN / Breathe OUT, 2021

3D printed 100 % biobased and biodegradable polymer blend

© Adam Šakový

All natural materials age and change over time. Whether it is a desired or unwanted property, we have to count with it and therefore we should approach the material features differently too. Within the design research project Breathe In/ Breathe Out we set up the goal to develop a unique scents library for bioplastic materials (NUATAN). This would on one hand help customers to distinguish between synthetic and natural plastics and on the other, create a new relationship with these new materials that suddenly gets their own identity/ story.

In 2019 Office MMK and Craftings Plastics Studio received a grant from the Fritz und Trude Fortmann-Stiftung für Baukultur und Materialien to develop the Breathe IN / Breathe Out. During Milan Design Week (Alcova) 2019 we shared first outcomes and presented a modular 3D printed mesh wall and first steps of the scent development. Visitors were excited about having the possibility to smell the materials and since we tried a lot of different smells it brought them to their past and opened memories. In 2020 we collaborated with Studio Omer Polak and continued to explore the sense of smell as well as the different modular wall systems. Since 2020 the scents have being developed in collaboration with the scientist Karol Červenčík. What we did for the exhibition in Vienna was a recreation of selected aroma-active substances that are present in the material by conducting a specific chemical analysis. The combination of the most prominent substances from the analysis was the smell that we (who process the material) know very well from working with it. When heating up the material it releases this starchy/ sweety/ baking bread like smell which is unique for starch/ sugar based biopolymer blends. The other smell we create and implemented is our interpretation of the material decay. With these two unique smells we wanted to elucidate the audience what the material is like if it could communicate by its very own smell.

- Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK) Breathe IN / Breathe OUT, 2021 3D printed 100 % biobased and biodegradable polymer blend © Adam Šakový

- Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK) Breathe IN / Breathe OUT, 2021 3D printed 100 % biobased and biodegradable polymer blend © Adam Šakový

Presenting the scent of a material is challenging and during the process we explored different options. Right from the beginning it became clear that the use case should embody the design principles of circular design such as being modular, easy to disassemble and repair and very versatile. We started to develop a modular room divider with a very soft and light appearance which can be applied in hotels, offices and domestic environments. The system is based on a single module and eight possible connections which allows for multiple ways of assembly and gives the room divider an organic appearance. The modular system also allows to integrate different scents.

MAK: For the circular economy, it is important to use biological cycles on the one hand and to keep resources in technical cycles for as long as possible on the other.

Your design approach and use of materials aim to keep material cycles closed, an important factor for climate care.

What is your definition of circular design? How can we best keep materials in the loop? How can designers contribute? What’s your next step in your practice?

The crafting plastic! studio: For us circular design is something that has the ability to circulate both within the product consumption circle & biological cycle, depending on materials used in the product or object. From finding accurate eco-friendly resources for the primary materials through its efficient and low energy consuming production process, following its multiple use until the phase of repair/ recycling of the single materials. When using biobased and biodegradable monomaterial, the bioplastic circulates within the biological cycle after they are appropriately decomposed and can turn into nutrients, natural CO2 and water and can nurture the soil for another planting round.

We think that designers can contribute with their ability to understand various processes and mediate between disciplines for better interdisciplinary outcomes. Our goal is to translate some of the biobased materials into practice and help to make a positive impact on different scales.

Vlasta Kubušová, Miroslav Král (crafting plastics! studio), Moritz Maria Karl (Office MMK)

Breathe IN / Breathe OUT, 2021

3D printed 100 % biobased and biodegradable polymer blend

© Adam Šakový

In the near future we are going to focus more into the collaboration with biologists to create biomaterials allowing us to burden natural resources as little as possible. The next step for us is continuation in the new research on aroma active biomaterials (and living materials), starting in January as part of our research through the Fulbright Scholarship program in the U.S. We are also planning to introduce new biobased solutions for the eyewear industry during next year.

Together with OFFICE MMK we are now planning to introduce the modular system wall as a product that could be bought and easily set up at home, in an office, restaurant or in other public spaces. The package will consist of 30 modular pieces. We hope this is the way how we can introduce these ideas and solutions directly into practice and by getting feedback be able to improve the scent-biomaterials innovation.

The interview was held by Marlies Wirth, Curator, Digital Culture and MAK Design Collection